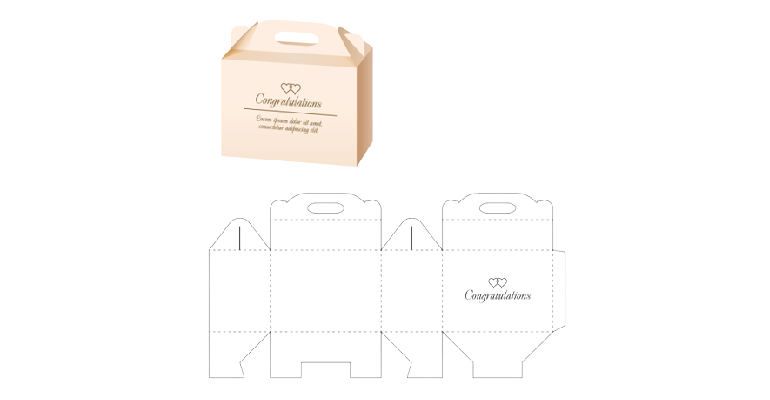

Die cut boxes

Die cut box are very customizable corrugated cardboard boxes manufactured to fit any type of size, shape, and need. They are popularly known as die-cut boxes as they are cut from corrugated material’s plain sheets with the help of a machine called a die cutter.

These types of boxes slot together with no requirement of packing tape and are sufficiently robust for various types of packaging. These cardboard boxes are an ideal option for postal campaigns that properly feature every packed product and they provide high-quality packaging for every type of item. These types of boxes come in varying lengths, colors, widths, and heights.

This box specifically designed by various design specialists or engineers, and the machine called a die press is set and then configured to cut out the cardboard. After cutting off these boxes these boxes could be further customized by the addition of special graphics that might consist of warnings, information, and company logos. You can also check cardboard price here by contact us page.

These types of boxes are the best option for e-commerce applications or as a type of transit packing. These boxes are easy to pack and assemble and look attractive, which makes them perfect for various packaging purposes.

The die cut carton box offers improved awareness of the business and also offers a professional appearance. It offers a good level of transit protection and makes them suitable for industrial packaging. The utilization of these boxes satisfied every customer to a great extent and could meet their small requirements.

The boxes possess access holes or perforated lines, they could be bought in customized finishes, sizes, designs, and prints. The boxes are manufactured with the help of premium quality raw materials via sophisticated machines with the help of professionals. Moreover, the boxes are ideal for crockery packing and avoid breakage during transportation.

Die cut carton box methods

Die-cutting is the most famous process in the packing industry and has evolved to become a most desirable manufacturing process. Die cut corrugated boxes in the packing industry make use of a die to cut materials into a line of varying designs, shapes, and patterns.

The Die cut box process is highly valuable and is rapid, easier, and cost-effective to produce packing in high quantities. The leftover material is collected and recycled after the process. Moreover, the die-cut process includes varying functions:

Cutting: The machine cuts to right through the material.

Scoring: it leaves an impression or partial cut over a specified area.

Creasing: designs fold lines just for easy construction.

Perforating: a series of small cuts left for convenient tearing.

Creasing is highly utilized in the construction of corrugated packing boxes ( Cutting box )and every function performs a purpose for varying types of packing materials.

Apart from having various functions, it also performs various methods and these methods open up a new era of design possibilities, and permits efficient packaging.

Several die-cutting methods include:

Blanking: It arises from an accurate degree of flatness and is sliced via clipping from the exterior edge.

Drawing: It can pull up the material to a predetermined length and is utilized in creating lean packing.

Forming: It is used to shape a raw material over a curved surface and is utilized to construct various cylindrical shapes.

This die: Cut procedure is beneficial for die-cut packaging and provides a unique business along with a sophisticated feel.

Features of Die cut box

- Lightweight and easy to use.

- Provides high strength.

- Is moisture resistant and impactful.

- Entirely recyclable and pure.

- Environment friendly and sustainable.

- Is a 5 ply box.

- Durable corrugated box.

- Offers dimensional accuracy.

Die cut box also known as punching boxes die cut can be done on automatic punching and manual punching machine die cut punching boxes is because the box is a punch by die made of wood and a blade of creasing and cutting.

The benefit of the die cut is a box:

- Die cut finishing is too sharp no scrap remains at the edge.

- creasing of the box is best to get so sharp crease because of a blade that fold from the area we want.

- die cut help u to make a cut from anywhere in the box for example if it’s a fruit box u can do a hole which is mainly required in mango boxes, chilli boxes, Chikko boxes, and Anar boxes, capsicum boxes.

Mostly for the export of corrugated boxes or to get export quality corrugated box peoples use die punch boxes, You can search Asianpackaging as an die cut box maker in Vapi Gujarat.

FAQ’s

1. What is meant by a die cut box ?

It is a type of box that is cut from sheets of single wall corrugated via a cutting machine and are very robust for varying packaging uses.

2. How to make die cut box ?

These boxes are manufactured by using varying types of rubber and foam pieces and then they are glued over the die. Die-cut machine firmly presses die into cardboard that leads into cut-out shape.

3. What is meant by die cutting?

It is a procedure in which a die is taken in use to cut through various materials like cards and paper over a die process. This procedure permits the creation of a unique cut into the material at various times.